Hi—

First thing: I’m going to share with you below how to make granulated maple sugar from liquid maple syrup. It’s shockingly easy.

Second thing: Despite the fact that you’ll see the words “refined” and “unrefined” below, this is not a “healthy sugars” piece. It’s an exploration of certain maple-related things I wanted to know more about: 1) How do I make maple sugar from maple syrup?; 2) What exactly distinguishes so-called “unrefined” from “refined” sugars?; 3) What gives maple syrup (or sugar) its distinctive flavor?

Third thing: I came up with a delicious and easy cookie (and, by chance, gluten-free) recipe that takes advantage of my new bounty of maple sugar: Chewy Maple-Pecan Cookies. I can’t stop eating them. I’ll share the recipe here in my “p.s” supplement*.

As always, thank you for reading this. Have a good weekend. Talk to you soon.

Brian

*Formal Assignment P.S. is for paid subscribers. It’s just $5 a month—or even less for an annual subscription.

MAPLE SYRUP and REFINED vs. UNREFINED SUGARS

For me, the appeal of maple sugar is the flavor: having maple in solid as opposed to liquid form means it can easily be swapped in where recipes call for granulated sugar (cakes or cookies, for example), adding maple flavor without messing with the water content of a recipe.

Some people are drawn to maple syrup and sugar because they’re categorized – in opposition to refined white cane sugar or corn syrup – as “unrefined” sweeteners. But – pop quiz – what exactly do the terms “refined” and “unrefined” even mean in reference to sugars?

Unrefined sweeteners essentially result from the simple removal of water from a raw ingredient. Bees put to use a specialized bodily function to evaporate water from nectar, thereby concentrating it into honey. Humans, lacking the corporal advantage of bees, rely on heat to cook off water from naturally dilute tree (maple, birch, or palm) or agave saps.1 The resulting syrups and sugars are simply concentrated versions of the raw ingredients and mostly retain the non-water components that existed in the raw ingredient — with the exception of a) any volatile molecules that escape because they can’t withstand the heat required for evaporation and b) altered compounds due to chemical reactions (such as caramelization) that occur during the concentration process.

Refined sugars, on the other hand, have submitted to more processes than simple evaporation. All cane and beet sugar is refined to some extent; Harold McGee explains in On Food and Cooking that “Cane and [sugar] beet juices include many substances—proteins, complex carbohydrates, tannins, pigments—that not only interfere with the sweet taste themselves, but decompose into even less palatable chemicals at the high temperatures necessary for the concentration process. Cane and beet sugar must therefore be separated from these impurities.” Sugarcane stalks are crushed to release their sweet juice, which gets boiled down, then “heat and lime…coagulate and remove proteins and other impurities.” A spin in the centrifuge follows, to separate the liquid molasses from the crystallized sugar, then carbon is used to decolorize the sugar (It gets added to the centrifuge then removed along with the impurities it has attracted). “The final crystallization process,” writes McGee, “is carefully controlled to give individual sugar crystals of uniform size. Our table sugar is an astonishingly pure 99.85% sucrose.”

WHAT GIVES MAPLE SYRUP ITS FLAVOR?

In Nose Dive, Harold McGee describes maple syrup’s component smells as “sweet, fruity, fenugreek, toasty, bready, vanilla, sharp”. The source molecules of these aromas are “furans, furaneol, sotolon, pyrazines, maple lactone (cyclotene, methyl cyclopentenolone), vanillin, acetic acid”. There’s a bit of sotolon in wheat and rye2, but the most important source of it is fenugreek seeds, which are processed in order to isolate sotolon for use as a flavoring in artificial maple syrup.

A LITTLE HISTORY

While technology has made it easier for maple syrup producers to collect and concentrate the sap of the sugar maple (Acer saccharum) – “Buckets are little more than decoration these days, replaced by tubing that draws the sap out with the aid of a vacuum pump”, writes David Staba – the essential process and final product remain the same: dilute sap is collected, concentrated via evaporation, and bottled.

The sugar maple is native to North America, and Native American tribes including the Algonquins, Iroquois, and Ojibways are believed to have been tapping the trees for its sweet sap since long before the arrival of Europeans on the continent3, and since their pottery couldn’t withstand the temperatures required for boiling, they developed other ingenious, if less rapid, methods of concentrating the sap: 1) repeated freezing (which separated pure water in the form of ice crystals) followed by removal of ice; and 2) Placing sap in a hollowed-out log and adding a heated stone, repeatedly, to gradually boil off the sap’s water content (See the Cornell-produced video below).

VIDEO LINK: “History and Production of Maple Syrup,” College of Agriculture and Life Sciences (CALS), Cornell University

WHAT’S MAPLE SUGAR?

Maple sugar is quite simply what we get when we continue to concentrate maple syrup (letting it reach around 250 to 260 degrees Fahrenheit), to the point where “it will crystallize when the syrup cools.”

RECIPE: MAPLE SUGAR

I had no idea until last week how easy maple sugar is to make. If you have an instant-read thermometer (or a candy thermometer), a stand (or hand) mixer, and, of course, some maple syrup – along with half an hour of time – you’re equipped to convert maple liquid to crystalline solid. (Alright, you also need a saucepan and a silicone spatula, but I wanted to show you the respect of assuming you have those kitchen necessities – plus, I didn’t want to crowd the sentence.)

I sought out Youtube videos and was convinced by one that I, too, could make “Canadian sugar”, as the video’s creator called it.

---

INGREDIENTS:

---

vegetable oil or unsalted butter for brushing the pan

at least 470g (1 1/2 cups) pure maple syrup

---

INSTRUCTIONS:

---

1. Line an 18-by-13-inch half-sheet pan with parchment or a Silpat. Set aside. Have your stand mixer bowl and paddle attachment (or large mixing bowl and hand mixer), along with a heatproof flexible spatula, ready to use.

2. Place the maple syrup in a saucepan that is small enough to make the syrup at least an inch deep and tall enough that the side rises several inches above the surface of the syrup to allow room for it to boil ferociously. Very lightly brush the top edge of the pan’s interior with oil or butter; This helps to prevent boiling over. Place an instant-read or candy thermometer in the syrup and, over medium-high heat, allow the syrup, unmolested, to reach 257 to 262 degrees Farenheit (127 Celsius).

3. Immediately (and very carefully) transfer the hot syrup to your mixing bowl, scraping our as much as you can with a flexible spatula. Gradually raise your mixer’s speed to medium and mix the syrup. It will soon become opaque, then it will begin to crystallize. Continue to beat it until it resembles granulated brown sugar. You may need to scrape the sides of the bowl with a metal spoon or offset spatula to break up solidified maple sugar; continue to beat after scraping to break it up.

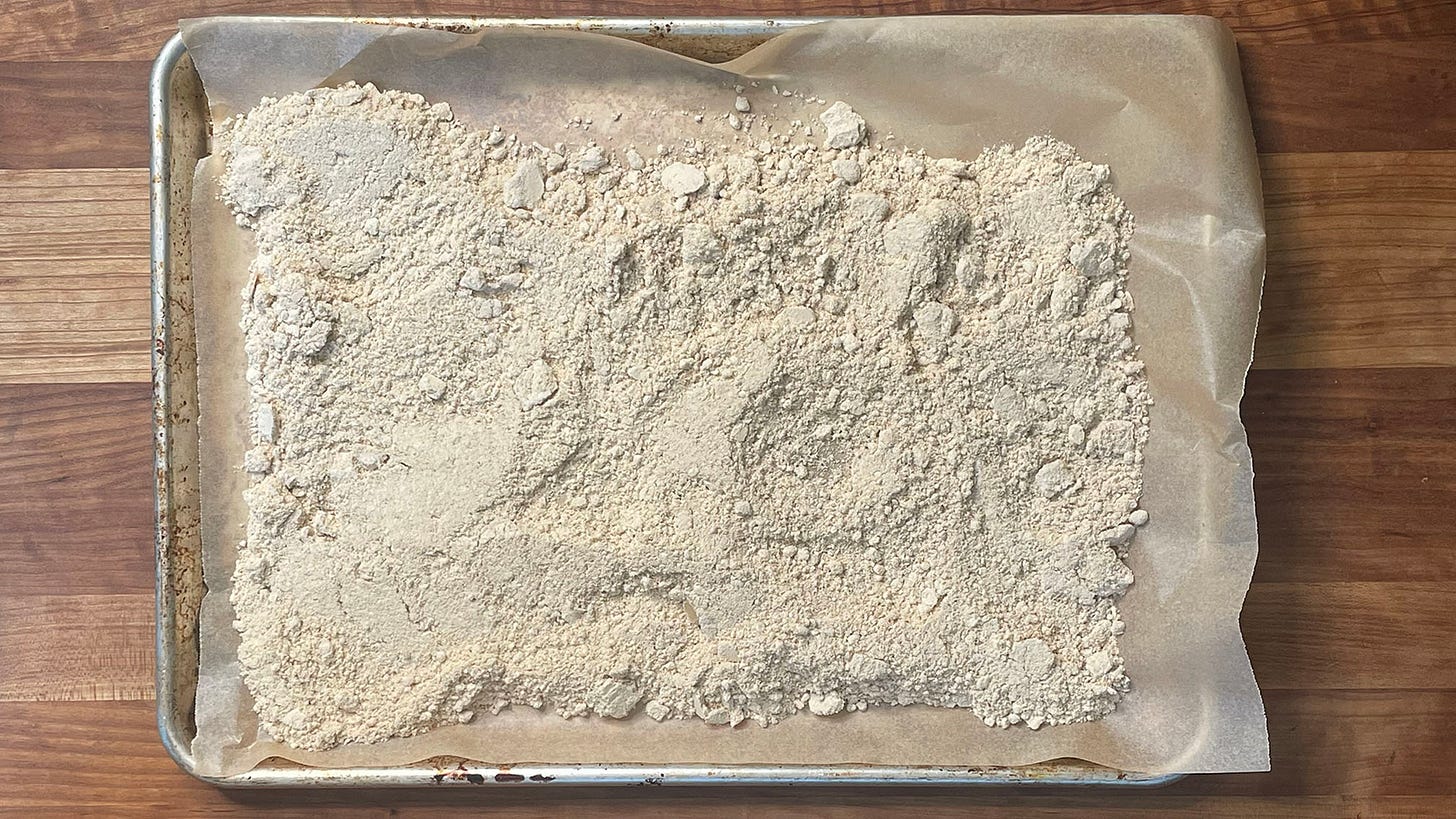

4. Once the maple sugar is granulated and fairly cool, spread it on the lined sheet pan and place it in a (powered off) oven to cool to room temperature. Once cooled, transfer it to an airtight container for storage. Store it as you would brown sugar and know that you may need to similarly shake it up to get rid of clumps. (If you really want it to be perfect, you can put it in a food processor or blender and run it through a sieve. But I didn’t do that.)

McGee, H. (2007). On Food and Cooking: The Science and Lore of the Kitchen. United States: Scribner. Pages 663-671.

Mcgee, H. (2020). Nose Dive: A Field Guide to the World's Smells. United Kingdom: John Murray Press. Page 284.

McGee. On Food and Cooking. Page 668.

Going to try this! Maple sugar is so damn expensive I love the idea of making it myself!

If you stop processing when it starts to thicken and dry will it be like the stuff used to make hard candy? I have seen people make this by hand starting with carob syrup. Can one use carob syrup to start instead of maple syrup which is not a Mediterranean ingredient?